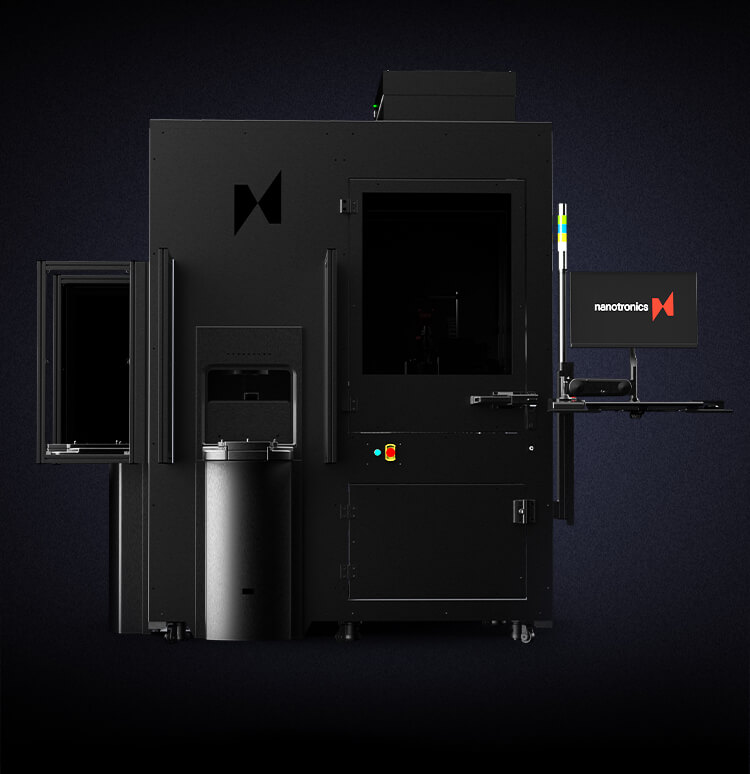

With detection features that automate the inspection process

Nanotronics’ loader control software features group and individual wafer handling. The CPS inspection software can save the sequencing in a recipe to give the user highly repeatable results. The software also allows you to mark wafers to speed up a quality control process. The control software keeps wafers safe by reporting and handling all motion control errors.